Art Engineering: Design and Technical Office

Art Engineering and Design Office: Securing the Creative Process

Featured Art Engineering: Technical Expertise

Art Engineering: Structural Expertise and Design

The transition to monumental scale or the use of complex materials requires in-depth technical analysis to ensure the stability and safety of structures. Under the direction of our founder and consulting architect, our integrated design office ensures cross-functional coordination between artistic intent and construction requirements at art project.

Technical Feasibility Studies and 3D Modeling:

We analyze geometric and mechanical constraints to validate the viability of the structure from its inception.

Structural Engineering and Regulatory Compliance:

To ensure the safety of our facilities, we work with partner engineering firms that specialize in preparing structural calculations and ensuring compliance with international safety standards.

Innovation and R&D: Technical Material Sourcing

We define innovative processes and source the appropriate materials (metal, technical glass, blown neon, composite panels) to meet the specific challenges of the exhibition venue.

Technical Art Prototyping: Validation and Sampling:

We produce samples and scale models to validate assemblies and interactions between materials before going into production.

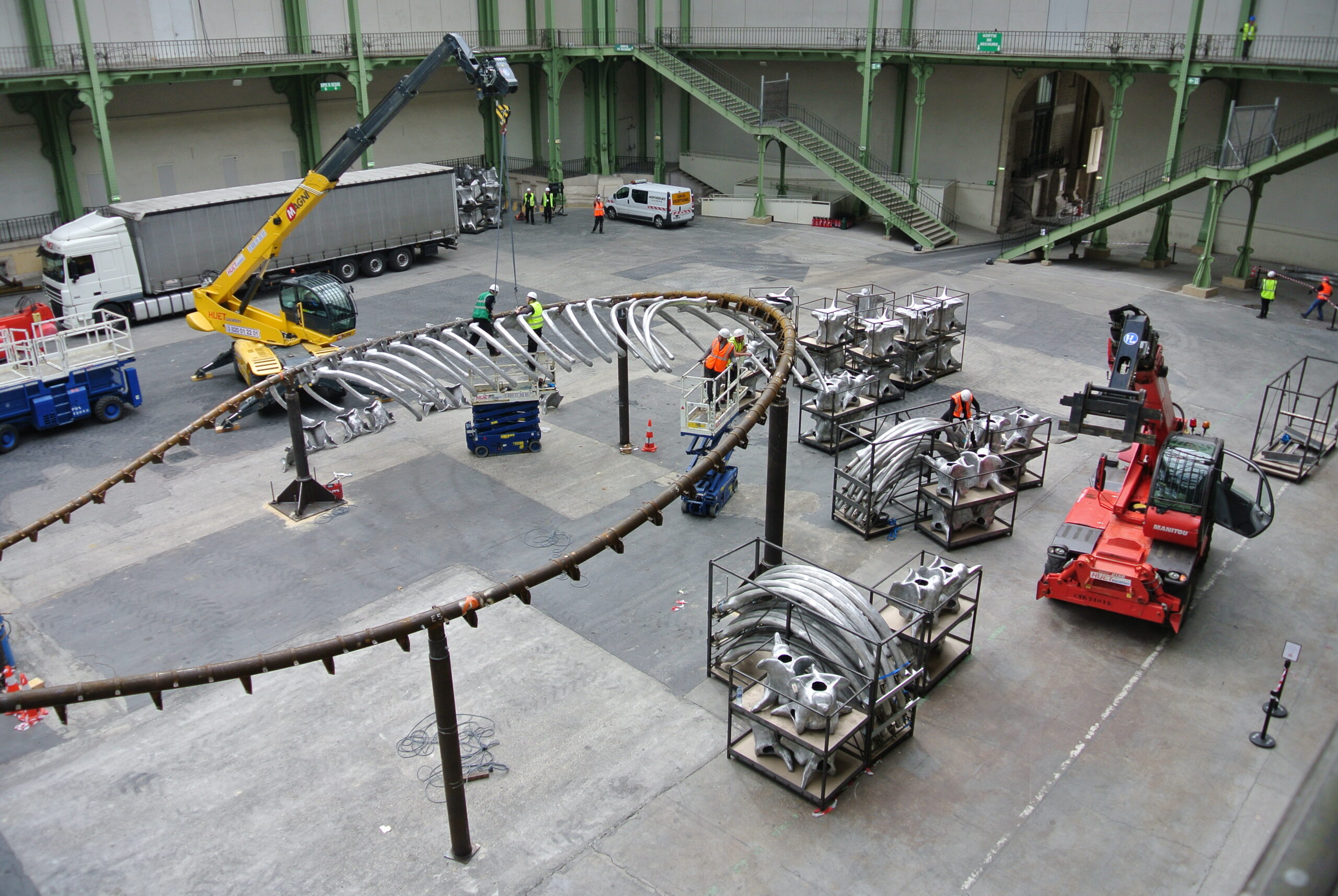

From Art Engineering to Monumental Fabrication

The strength of art project lies in the immediate synergy between our design office and our manufacturing infrastructure. This integration guarantees total responsiveness and absolute fidelity to the work throughout the manufacturing cycle.

21,500 sq ft (2,000 m2) Facility and Lifting Capacity:

Our production site is equipped with a 10-ton overhead crane, enabling us to safely handle and assemble structures of exceptional size.

Multi-material expertise:

Our teams transform steel, stainless steel, brass, as well as wood, technical glass, and composite resins within an organization of expert workshops.

Full Dry-Run Assembly and Validation:

Each project undergoes complete pre-assembly in the workshop, allowing sponsors and artists to approve the work before it is shipped.

Global Coordination and International Deployment

Art Project's engineering expertise extends to the final implementation phase. We are experts in art logistics, ensuring a smooth transition from the studio to major institutions around the world.

Logistics Engineering and Custom Crating (ISPM 15):

We design custom technical packaging and shipping crates that comply with international standards to protect the integrity of the artwork.

Customs Management and Global Transit:

We handle the complex administrative formalities involved in temporary or permanent exports to destinations such as London, New York, or Riyadh.

Worldwide Installation: Technical Supervision for Design

Our technicians travel worldwide to carry out on-site assembly and final anchoring, ensuring a finish that is identical to that approved in the workshop.

Request an Art Fabrication Feasibility Study

Our design office will validate the technical, regulatory, and budgetary feasibility of your project. Send us your file for a detailed analysis.