Art Fabrication: Supporting Structures

Art Fabrication: Engineering and Production of Support Structures

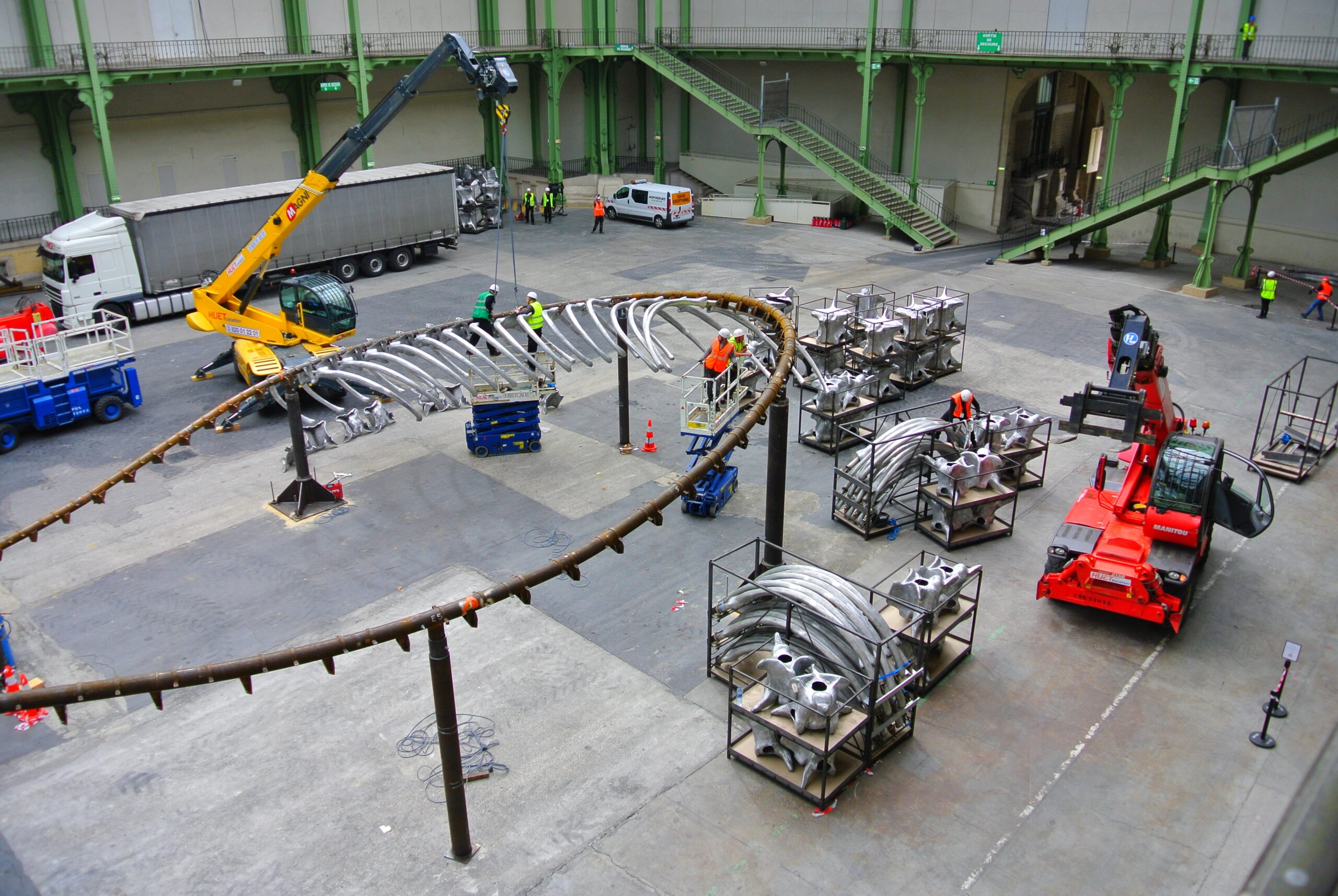

Since 1999, art project has been the technical lead for artists and institutions worldwide. From our 21,500 sq ft (2,000 m2) facility, we engineer and fabricate bespoke frames, pedestals, and internal structures that ensure the stability and durability of the most ambitious monumental projects.

Featured Art Fabrication: Supporting Structures

Art Fabrication Workshop: Supporting Monumental Works

With a 2,000 m² workshop and a 10-ton overhead crane, art project has the industrial capacity to manufacture structures of exceptional size. The precision of the workshop manufacturing process guarantees perfect assembly during final installation.

Production of complex metal frames:

We manufacture high-precision mechanically welded structures (steel, aluminum, stainless steel) capable of supporting monumental loads while maintaining millimeter tolerances.

Engineered wood Supports: Precision Machining and Shaping

For projects requiring wooden load-bearing structures, we use wood species selected for their dimensional stability, suited to the constraints of long-term exposure.

Art Prototyping : Load Testing and Structural Validation

Each critical structure undergoes assembly and validation testing in the workshop, ensuring the safety of subsequent phases for production agencies and artists.

Art Engineering: Structural Design and Integrated Office

The success of a monumental work or a complex design piece begins with a complete understanding of the forces at play. Our design office transforms artistic intent into a masterful engineering challenge, ensuring the viability of what supports the work, often in an invisible or integrated way.

Structural Engineering: Regulatory Compliance and Calculations:

Our engineers validate the strength of load-bearing structures against weight, wind, and seismic stresses, ensuring complete safety for installation in public spaces.

Multi-Material Frames: Integrated Metal and Wood Design:

We develop internal structures in steel, stainless steel, or high-density wood, selecting materials for their rigidity and compatibility with the final finish of the work.

Technical Interfaces: Precision Anchor and Fastening Systems:

We carefully study fastening systems and ground connections, enabling optimal load transmission and discreet integration into the final environment.

Global Art Logistics: Installation of Support Structures

A supporting structure is only effective if its installation is properly managed. Since 1999, art project has been coordinating the worldwide deployment of technical supports, managing the constraints of export transport and on-site installation with absolute rigor.

International Logistics: Custom Export Crating (ISPM 15):

We design specialized transport frames that comply with ISPM15 standards for shipping large structures anywhere in the world by sea or air.

On-site Installation: Global Assembly and Anchoring:

Our teams travel worldwide to assemble and anchor load-bearing structures, ensuring that the finished work meets the expectations of galleries and institutions.

As-Built Documentation: Long-Term Structural Monitoring:

We provide all technical documentation relating to structures (as-built drawings, maintenance logs) to ensure long-term monitoring and stability of the structure.

art project positions itself as the guardian of the physical integrity of your creations, offering over 25 years of expertise in the shadow of works of art across the globe.

Request for Study: Structural Engineering and Analysis

Our design office will validate the technical, regulatory, and budgetary feasibility of your project. Send us your file for a detailed analysis.