Multi-material artworks

Multi-Material Art Fabrication

Featured Multi-Material Art Fabrication Projects

Multi-Material Art Fabrication Workshop

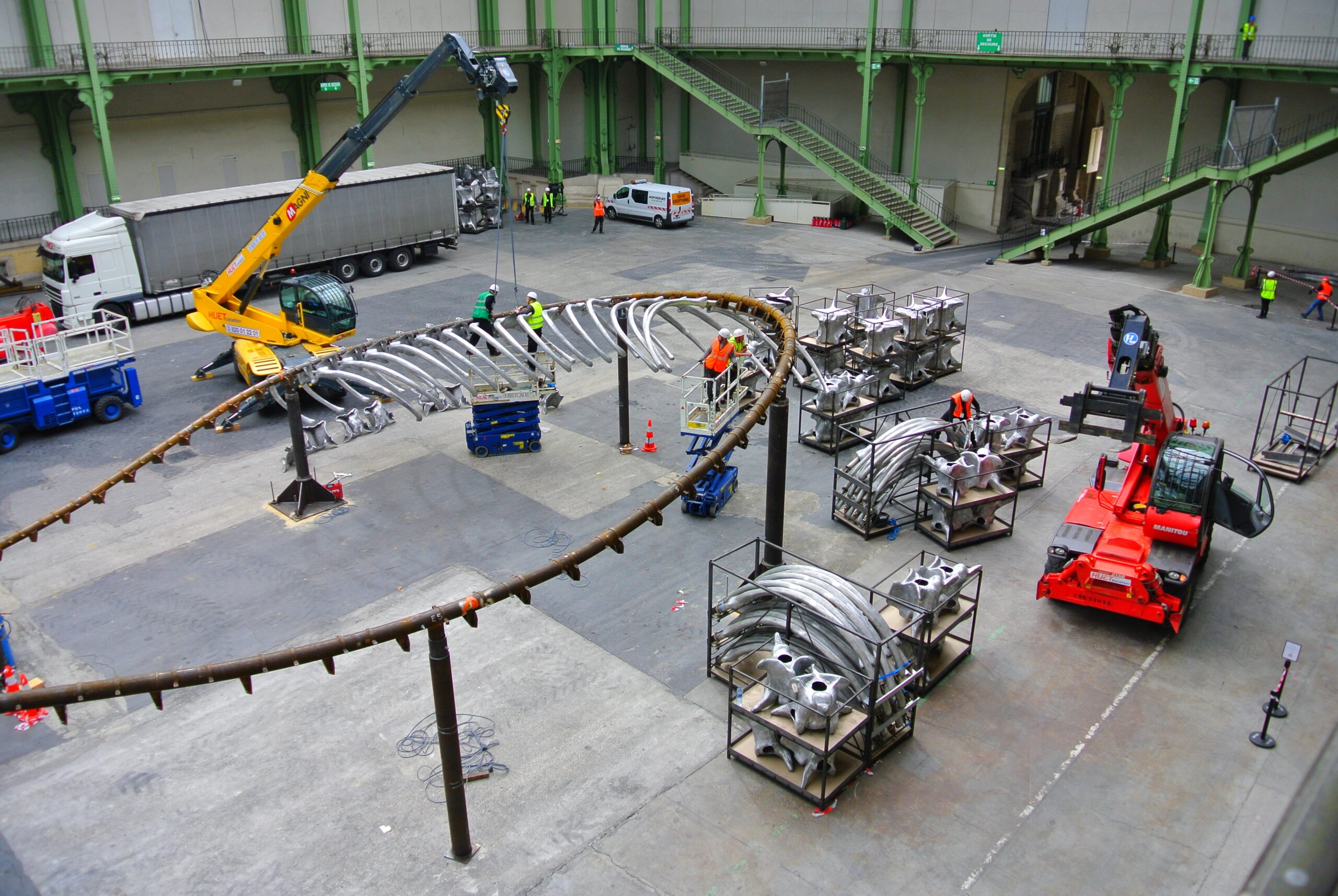

Our 21,500 sq ft (2,000 m2) production facility, equipped with a 10-ton overhead crane, is designed for large-scale multi-material assembly. Centralizing our expertise allows for rigorous quality control at each interface between materials.

Technical Woodwork and Architectural Cladding:

We manufacture high-precision wooden cladding that attaches to our metal structures, providing a flawless finish for art, scenography, or design.

Structural and Technical Glass Integration:

Whether it's structural glazing or engraved glass, we are experts in installing it safely in wooden or metal frames.

Precision welding and finishing:

Our technicians perform the metal assemblies (TIG/MIG) necessary to hold the structure in place, while preparing the surfaces for wood or glass finishes.

Art Engineering and Structural Support

Managing a project combining wood and glass often requires an invisible or integrated metal support structure. Our in-house design office is involved from the design phase onwards to resolve issues relating to the assembly of metal, wood, and glass.

Structural Engineering and Metal Frameworks:

We design internal steel or stainless steel frames that can support solid wood cladding or large glass panels.

Advanced Hybrid Fastening Solutions:

We develop technical solutions for bonding metal to glass and wood, anticipating differences in thermal expansion to ensure the stability of the workinternationally.

Multi-material prototyping:

Before final production, we create prototypes to validate the visual harmony between the wood grain, the transparency of the glass, and the precision of the metal.

Global Art Logistics and International Installation

Since 1999, art project has been transporting and installing hybrid works on every continent, fromEurope to the Middle East. Handlingartworks that combine fragile glass and dense wood requires flawless logistical expertise.

Custom packaging and crating (ISPM15):

We design technical packaging adapted to the hygrometric sensitivity of wood and the fragility of glass, while securing the internal metal structure.

Global installation and on-site assembly:

Our teams travel all over the world to carry out the final assembly of composite structures, coordinating lifting equipment to ensure millimeter-precise installation.

Meeting Institutional Deadlines and Project Management:

We guarantee that deadlines will be met for public order inaugurations and gallery openings, offering turnkey project management.

Request an Art Fabrication Feasibility Study

Our design office will validate the technical, regulatory, and budgetary feasibility of your project. Send us your file for a detailed analysis.